For legacy parts opened with the solidworks 2007 application edge flange dimensions appear only after editing existing edge flanges or rebuilding the part.

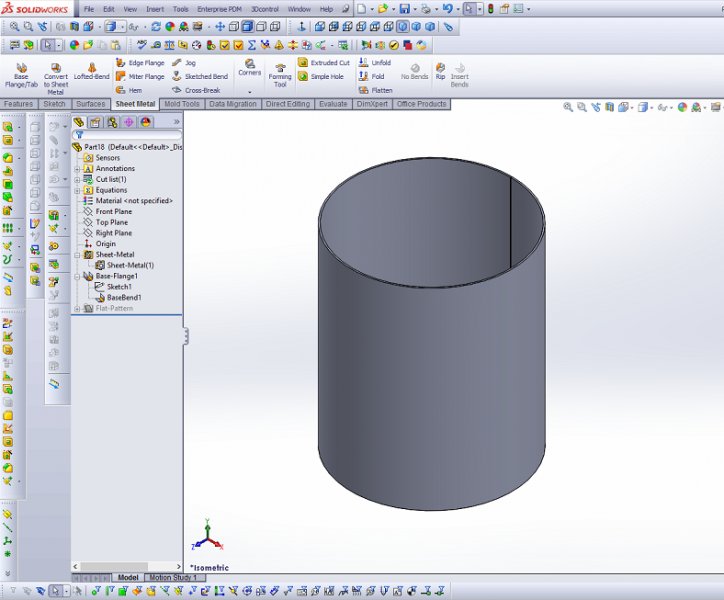

Solidworks rolled sheet metal with flange.

Flattening sheet metal bends.

Sketch line of the profile must lie on the selected edge.

Sheet metal edge flange on lofted bend i m working on a sheet metal part that s based off a lofted bend.

We have some parts that are rolled from sheet metal parts into tubes and cones i e no flat surfaces does anyone know how to do this in solidworks.

2016 solidworks help swept flanges for conical and cylindrical bodies.

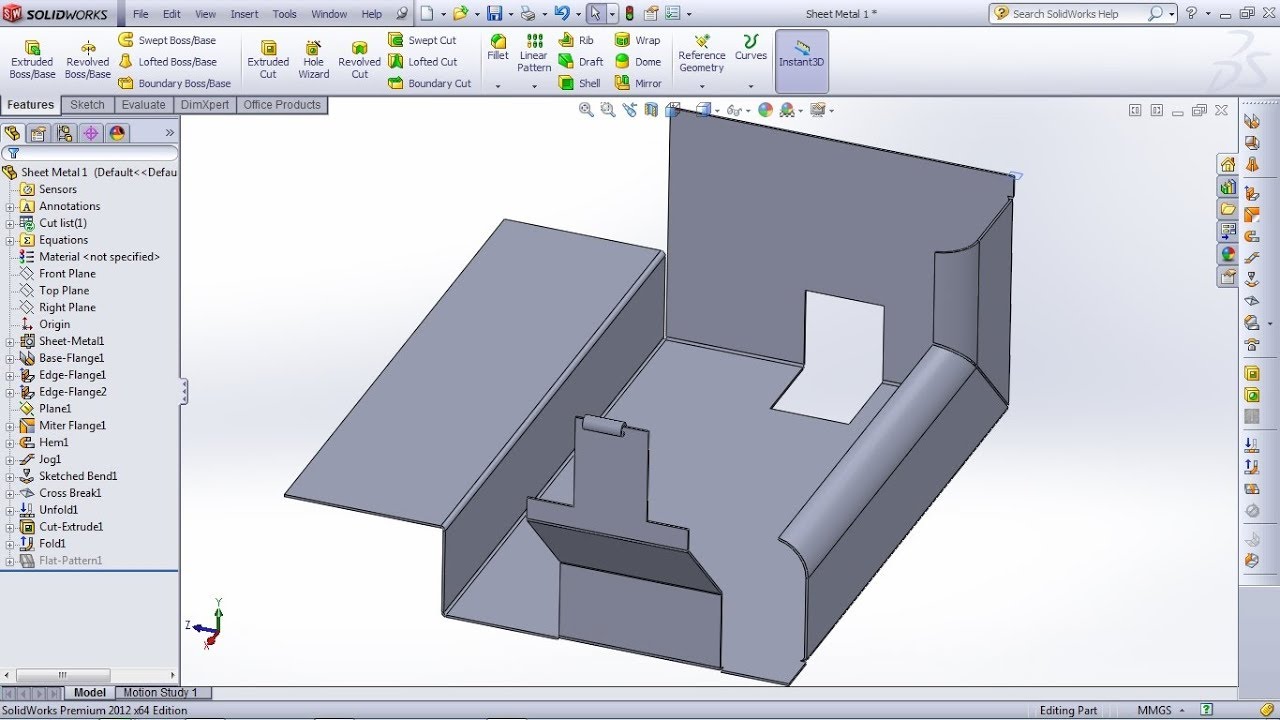

This video shows the difference between creating a swept flange and creating a miter flange in sheet metal.

Bjorn hulman jul 13 2017 11 13 am.

This is available only in sheet metal parts with flatten bends1 and process bends1 features.

From a part edge to rolled surface is there any way to convert an edge of a part in an assembly to the surface of a rolled sheet metal part and have it stay on the surface when flattened.

General edge flange characteristics include.

Thickness is linked to the thickness of the sheet metal part.

How to use swept flange in solidworks solidworks 2016 for engineers and designers 14ed misl dt by dreamtech press 838 00 https amzn to 2wzedj1 solid wo.

2016 solidworks help swept flange.

Click swept flange sheet metal toolbar or insert sheet metal swept flange.

You can roll back all bends from a sheet metal part in which bends have been inserted so that you can make additions such as adding a wall.

For more information about solidworks visit http.

In the graphics area.

The start or end point of the path must be coincident with the profile plane.

Like show 1 like 1.