Using a punch press style sheet hydroforming machines essentially force and fold a sheet of metal around a shape created by a female rubber diaphragm which molds to the shape of the male punch which is usually a.

Spinning process in sheet metal forming pdf.

Almost all metal are available in the form of sheet but following metal are generally used in this process like aluminium stainless steel copper brass tin silver gold.

The sheet metal parts that have circular cross section can be made by this process.

Tolling parameter roller diameter 2.

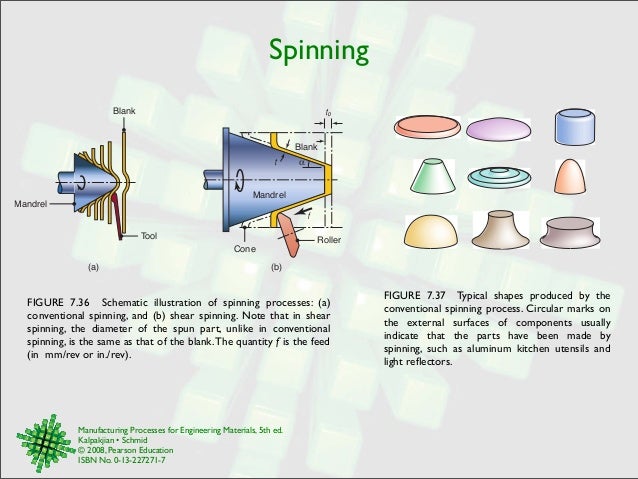

Metal spinning also known as spin forming or spinning or metal turning most commonly is a metalworking process by which a disc or tube of metal is rotated at high speed and formed into an axially symmetric part.

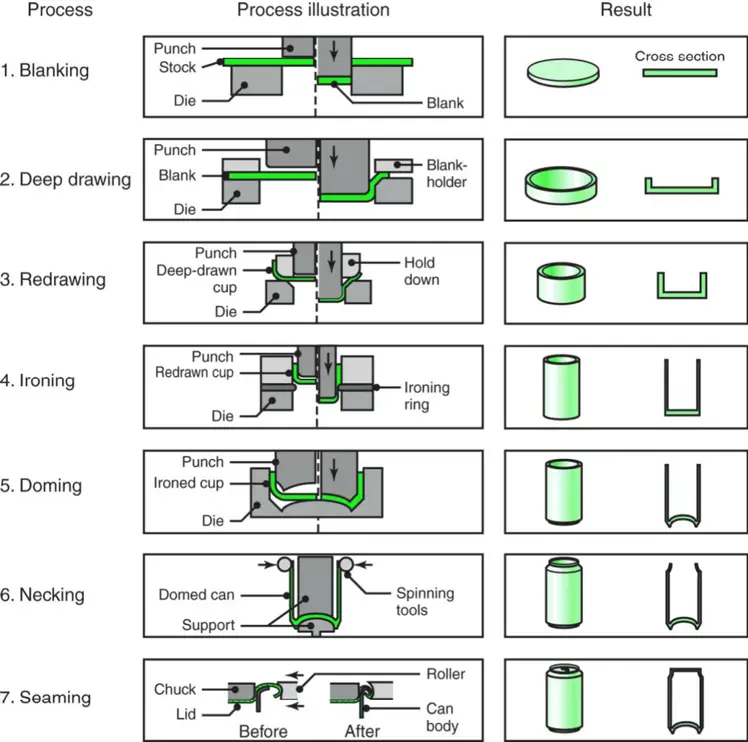

The sheet metal operations such as shearing blanking piercing notching trimming and nibbling.

To produce a component in metal spinning sheet metal is used.

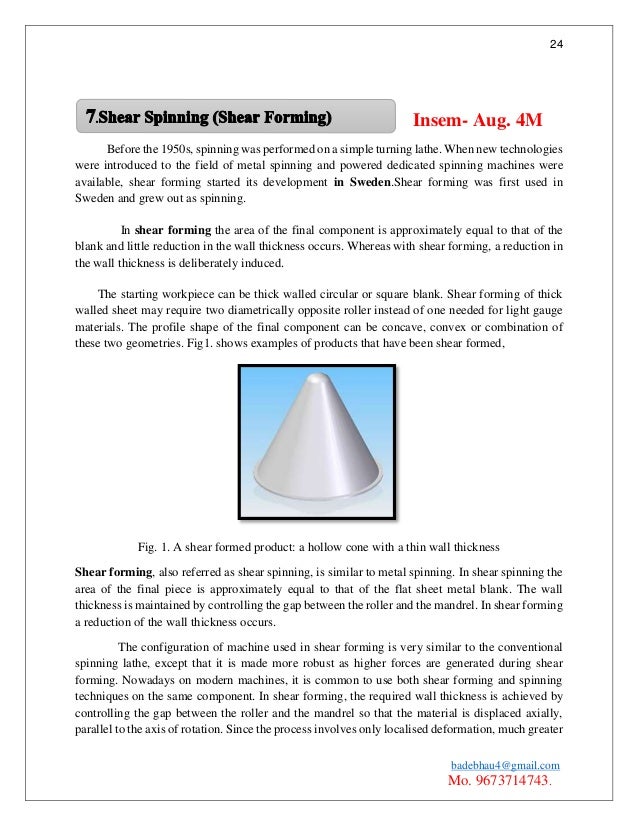

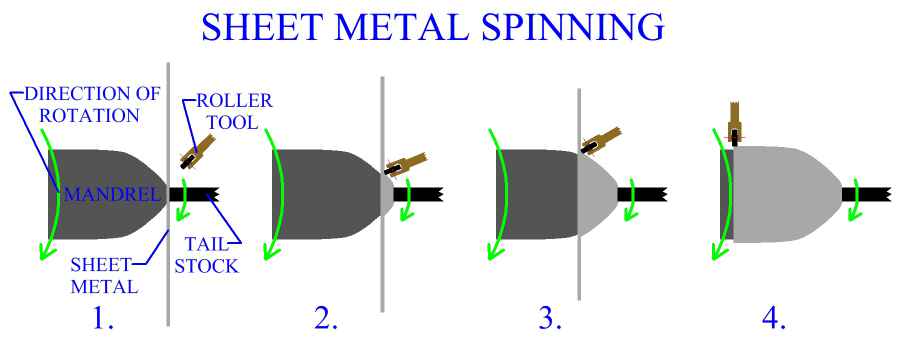

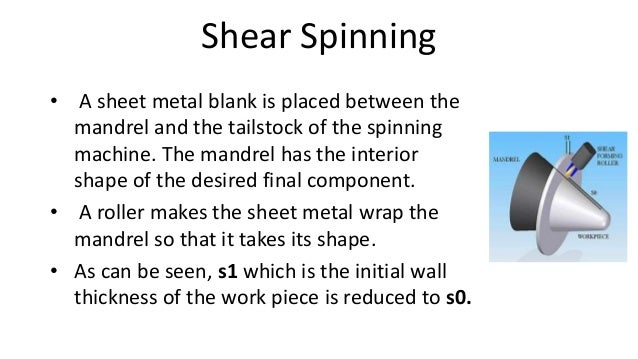

Spinning is a sheet metal forming process in which a metal blank is pressed over a rotating chuck or form mandrel with the help pressing tool to obtain axisymmetric hollow shell.

The rotation of sheet metal with high speed on a spinning lathe.

Metal spinning does not involve removal of material as in conventional wood or metal turning but forming moulding of sheet.

The result of the.

The axis symmetric components formed by using spinning sheet metal forming as shown in figure the spinning metal product such as aircraft engine parts jet engine parts truck wheels and etc.

Deep drawing is a compression tension forming process involving wide spectrum of operations and flow conditions.

Under pressure the rubber and sheet metal are driven into the die and conform to its shape forming the part.

Rubber forming in bending and embossing of sheet metal the female die is replaced with rubber pad rubber pad forming rpf is a metalworking process where sheet metal is pressed between a die and a rubber block made of polyurethane.

The symmetrical parts can be formed over mandrels by using sheet metal spinning process.

The sheet metal processes are bending embossing coining spinning stretch forming and deep drawing.